Short on paper? Prime it yourself!

Paper shortages can be a painful reality for printing companies. The current paper shortage can hit these companies hard, and, in most cases, it is out of the companies’ control. For the duration of the pandemic and even now, the weakening of the global supply chain means that these shortages of resources such as paper aren't going to go away anytime soon. This correlating to the rising price of timber has affected the paper industry harshly. The shortage of paper is creating a large issue right now for those in the paper industry, because acquiring paper with a specialized coating is becoming exceedingly rare, not to mention specific dimensions of paper being outright impossible to acquire. This has led to drastic changes in what size paper can be used for printing in bulk. With the demand for paper being so high now, it’s making more and more sense for paper distributors to look towards alternatives when it comes to making specifically coated paper in house, rather than outsourcing it elsewhere. What if there was a way to have your own paper treated with primer, without having it ever leaving the building?

Benefits of Kompac UV and Aqueous Coatings

Laminating is a popular finishing process that has long been used to protect printed collateral and extend its lifespan, especially in situations where it will be handled repeatedly, exposed to the elements and at risk from spills. Restaurant menus are the classic example.

What do YOU choose? Lamination or UV and Aqueous Coating?

Watch how easy it is to enhance product packaging using Soft Touch for the surface, and then spot coat using high gloss to add dimension and shine! Spot coat...

UV Spot Coating for Print and Packaging

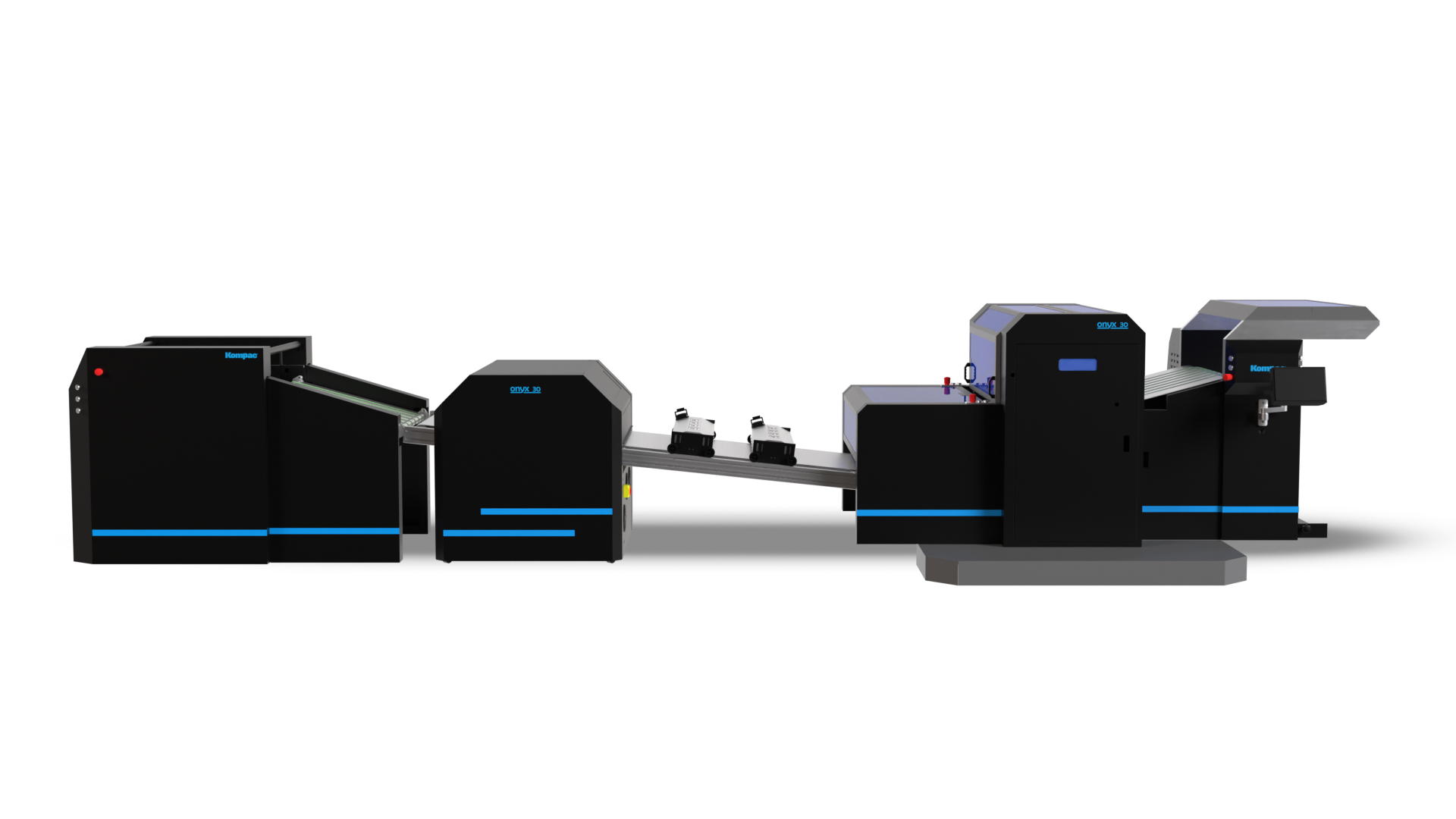

Kompac's Onyx 30 gives users the ability to apply Primers, UV, Aqueous, and Specialty Coatings to stock ranging from 3-30pt (60-600gsm), at speeds up to 6000 sheets per hour! Die-cut, perf and crease to produce outstanding finished products!

Save 2¢ a sheet by priming substrates for an HP Indigo

Choose from our EZ Koat 20, EZ Koat 30, or Onyx 30 (pictured) for converting untreated stock to Indigo-ready substrate. Compatible stocks include card stock, synthetics, plastics, lenticular and thin. After printing the primed stock, flood coat (EZ Koat 20/30) or flood and/or spot coat (Onyx 30) to enhance and enrich your prints.

NEW EZ Koat 2040 and 3040 Feeder and Stacker for 40" Sheets!

The EZ 2040/3040 Feeder & Stacker are production-level equipment that allows greater throughput on the Kompac EZ Koat 20 and 30 UV & aqueous coating systems. This coating machinery can now fit an incredible 20”x40” (50.8cm x 101.6cm) sheet with no loss in speed. It also accepts pallets (32” lift) to avoid hand-loading of sheets, and make the pre- and post press finishing a breeze!

Kompac to attend drupa 2020 in Düsseldorf, Germany

During the show you can talk to the experts about high-speed UV/Aqueous coating systems and find the perfect solution for your in-house coating needs. Being demonstrated at the show is the EZ Koat 20 Plus with chambered anilox, for running Soft Touch and matte coating. This 20” coating system can be configured for both sheets and web, inline and offline.

Kompac Celebrates 40 Years in Business!

“Reflecting on the past 40 years of operation, it’s inspiring to see how the products and team have grown. Family is at the heart of Kompac, and we’re proud to have built a global network, while maintaining our roots in the United States…..”